Mastering Scale Model-Building Process: Essential Skills and Technical Workflow for Precision Execution

- Dennis Asis

- 20 hours ago

- 3 min read

Model building is a craft that demands more than creativity. It requires a clear technical workflow, disciplined precision, and adherence to professional standards. Whether you are constructing architectural models, scale replicas, or prototypes, mastering the process improves both the quality and efficiency of your work. This post breaks down the key steps and skills needed to build models with accuracy and professionalism.

Understanding the Technical Workflow. Scale Model-Building Process

A well-defined workflow guides every stage of model building, reducing errors and ensuring consistent results. The process typically follows these stages:

Planning and Research

Start by gathering detailed information about the subject. Accurate measurements, reference images, and material specifications form the foundation. Sketching initial concepts helps visualize the final product.

Material Selection

Choose materials that suit the model’s purpose and scale. Common options include plastic sheets, wood, foam board, and metal. Each material requires different handling techniques, so understanding their properties is essential.

Cutting and Shaping

Precision in cutting parts is critical. Use sharp tools like hobby knives, saws, or laser cutters. Employ measuring tools such as rulers, calipers, and templates to maintain exact dimensions.

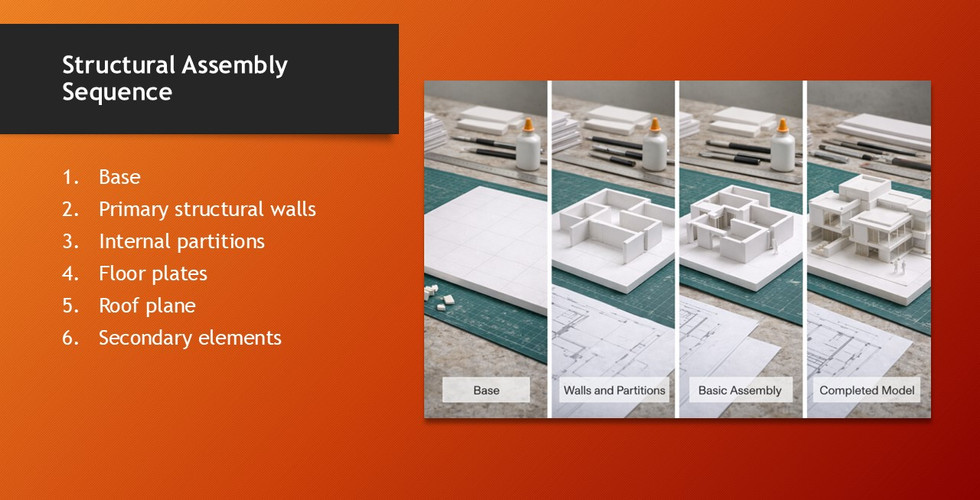

Assembly

Join parts carefully using adhesives, screws, or pins. Align components precisely to avoid gaps or misfits. Clamps and jigs can hold pieces steady during drying or fastening.

Detailing and Finishing

Add textures, paint, decals, or weathering effects to enhance realism. Sanding and smoothing surfaces before painting improve the final appearance.

Following this workflow helps maintain control over the project and minimizes costly mistakes.

Developing Precision Discipline

Precision is the backbone of professional Scale Model-Building Process. It requires patience and a steady hand. Here are practical ways to develop this discipline:

Practice Measuring Twice, Cutting Once

Double-check measurements before making cuts. This habit prevents material waste and rework.

Use Quality Tools

Invest in reliable cutting instruments and measuring devices. Dull blades or inaccurate rulers lead to errors.

Work in a Clean, Organized Space

A tidy workspace reduces distractions and helps keep track of small parts.

Take Breaks to Avoid Fatigue

Tired hands and eyes increase the chance of mistakes. Short breaks improve focus and steadiness.

Review Each Step Before Moving On

Inspect parts and assemblies carefully. Catching issues early saves time later.

Building precision also means accepting that some tasks require slow, deliberate effort rather than rushing to finish.

Meeting Professional Execution Standards

Professional model builders follow standards that ensure their work meets client or project expectations. These include:

Consistency

Every part should match the design specifications closely. Consistency in scale, color, and finish is crucial.

Documentation

Keep detailed notes and photos of the process. This record supports quality control and future improvements.

Problem Solving

Unexpected challenges arise in every project. Skilled builders adapt by modifying techniques or materials without compromising quality.

Time Management

Plan realistic timelines and allocate sufficient time for each phase. Avoid shortcuts that sacrifice precision.

Safety Practices

Use protective gear and handle tools carefully to prevent injuries.

Adhering to these standards elevates the model from a simple craft to a professional product.

Head over to our Resource Section for more insights and useful references.

Comments